Energy Recovery System

For Reverse Osmosis Desalination Plants

Product Outline

This product is a low noise and high efficiency energy recovery system that is designed

to reuse energy in high pressure brine discharged from the reverse osmosis (RO) membrane unit.

It is Japan’s first energy recovery system that boasts world-leading recovery efficiency.

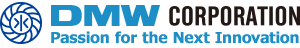

How the Energy Recovery System Works

Once DeROs is installed, 10,000 tons of fresh water can be produced

while the high pressure pump feeds half the volume of water

that would otherwise be required.

This means that power consumption will be about half,

enabling the user to drastically reduce the cost of fresh water production.

Japan’ first energy recovery system

boasting world-class efficiency of energy recovery!

-

- For fresh water production at 5,000 m3/day

- Energy recovery system’s efficiency: 98% or more

- Energy recovery system’s leakage rate: 1% or less

- Energy recovery system’s mixing rate: 1% or less

- Energy recovery system’s noise: 75 dB(A) or less

Piston speed is controlled with the two-step drive mechanism

enabled by our patented switching valve

to reduce both vibration and noise!!World-class energy efficiency will be achieved

when the system is combined with DMW’s high efficiency RO pump!The total head of the booster pump for DeROs

may be kept low, leading to reduced electricity costs!!!

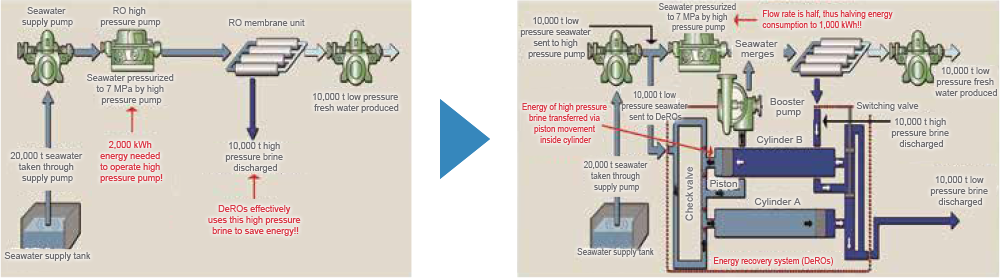

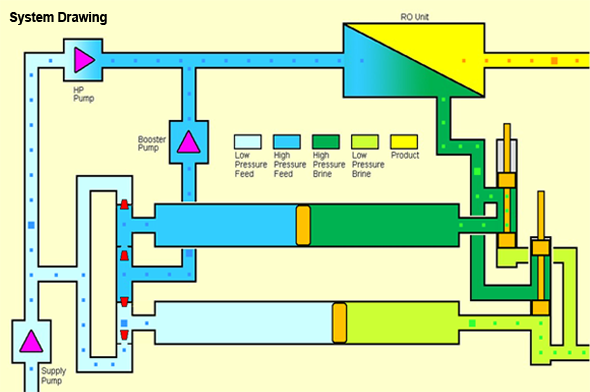

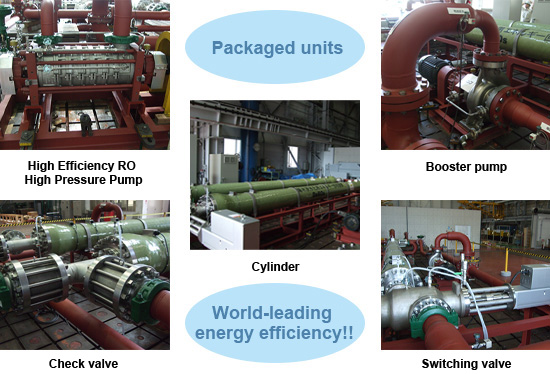

DeROs Configuration and Outside Dimensions

Material

| Part Name | Standard Material |

|---|---|

| Cylinder | Fiber-reinforced plastic (FRP) |

| Check valve | SDSS/DSS |

| Switching valve | SDSS/DSS |

| Booster pump | SDSS/DSS |

Configuration: Example for 5,000 m3/day production

- Cylinder (with piston)

- 2 pairs of switching valves and switching valve actuator units

- 4 check valves

- 1 booster pump (separately supplied)

Functions and Principles

There is a pair of cylinders arranged in parallel. As the position of the spool in each switching valve changes, low pressure seawater and high pressure brine are fed into the cylinders by turns.

High pressure brine discharged from the RO membrane unit is fed into Cylinder B, where the energy recovery process takes place as the high pressure of the brine is directly used to pressurize the low pressure seawater inside the cylinder.

The fluid-to-fluid energy transfer inside the cylinder enables the system to achieve an energy recovery efficiency of as high as 98%.

Cylinder A, the other cylinder, performs the feed process, receiving seawater from the feed pump while draining low pressure brine after energy recovery. The two cylinders repeat the energy recovery process and the seawater feed process alternately, allowing continuous energy recovery.

The booster pump works to compensate for pressure losses in the RO membrane and the overall system.

Combination with High Efficiency RO High Pressure Pump

When combined with DMW’s high efficiency RO pump, DeROs can offer world-leading energy efficiency! Combination tests at our factory may be conducted!

possible at desalination plants!!!

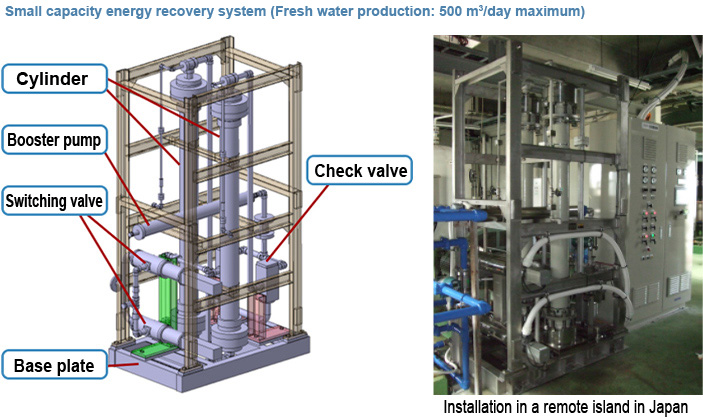

Small Capacity Model Available for Smaller Plants

High efficiency

- 96% or higher efficiency

- Less running costs

Modularization

- Shorter construction period

- Integrated transportation

Space saving

- Vertical installation possible

- Only small footprint required

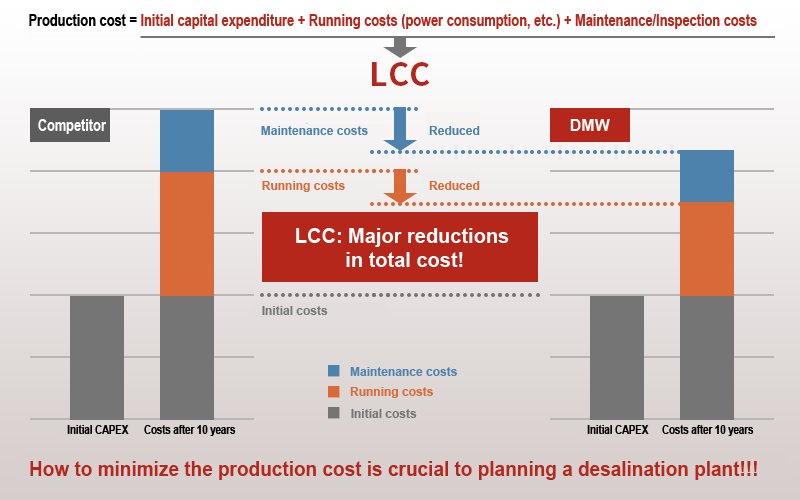

Life Cycle Cost (LCC)

Life cycle cost is an estimated cost of an item during its lifetime, including the initial capital expenditure as well as running costs, such as power consumption over five years or ten years, and maintenance and inspection costs.

Please compare DMW’s DeROs energy recovery system with other similar systems.

We are confident that DeROs will meet your expectations!!

Remote Monitoring System

DMW’s remote monitoring system allows you to monitor your DeROs in real time even from distant places, including its water production, electricity consumption, and operating status.

By analyzing the data trends recorded from monitoring, your staff can plan for better preventative maintenance and can even reduce the maintenance costs.

You can access the system from anywhere in the world

as long as you are connected to the internet or a 3G or faster mobile network service.

High Efficiency RO High Pressure Pump

Proposing optimal combinations with DeROs!

-

- World-class pump efficiency

- Compact design based on structural analysis

- A wide choice of materials: SDSS, DSS, austenitic SUS, etc.

- Pumps designed to operate at the best efficiency point, including booster pumps

-

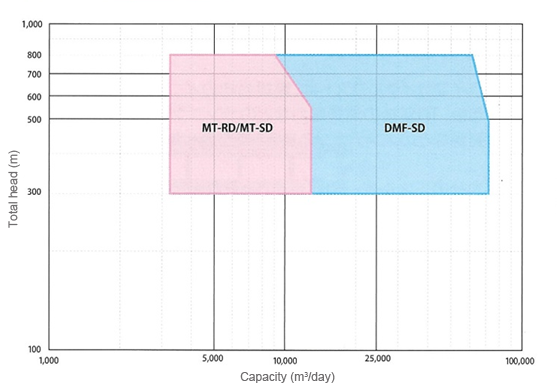

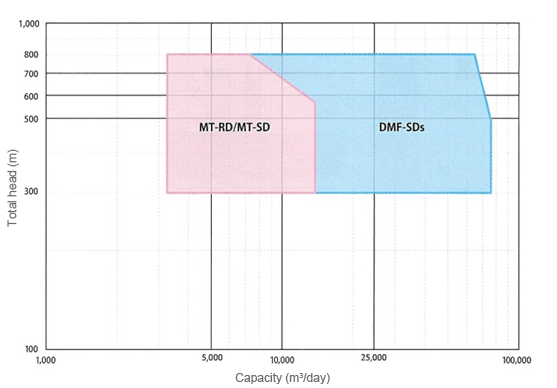

Three types of pumps optimized for DeROs

- MT-RD (radially split type)

- MT-SD (axially split type)

- DMF-SD (axially split type)

Pump specification optimized for DeROs

- Capacity: 5,000, 10,000, 25,000 m3/day

- Total head: 500, 600, 700 m

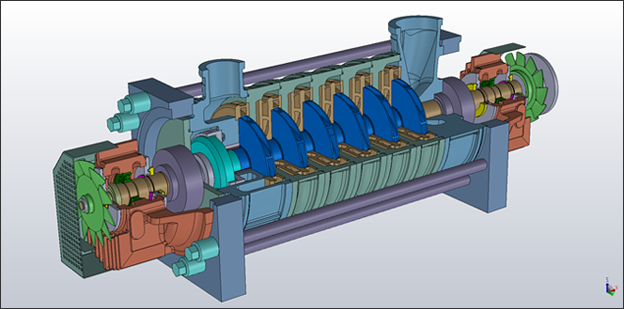

Radially split type high efficiency RO high pressure pump (MT-RD)

High Efficiency RO High Pressure Pump

Radially split type high efficiency RO high pressure pump (MT-RD)

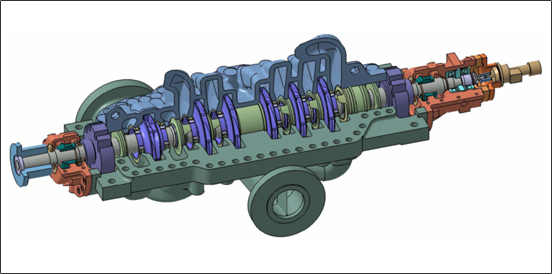

Axially split type RO high pressure pump (MT-SD/DMF-SD)