Design Engineering

Pump Design

Our design department mainly engages in the following two activities:

(1) Developing a basic plan according to the customer’s needs and satisfying the customer by proposing new technologies and designing reliable machines that achieve the desired quality levels

(2) Creating production drawing information needed to manufacture devices that fulfill the required functions

In each team of the design department, specialized engineers use analytical codes and develop computational and review programs in an effort to support DMW’s manufacturing.

In the area of pump design, they develop and design numerous types of pumps, including vertical mixed flow pumps, horizontal pumps, and high pressure pumps.

Our design engineers take into consideration various factors, such as operating conditions and geographical conditions. In addition, they perform CFD analysis, strength analysis, and/or sump testing according to the specification of each product. This leads to the development of optimal geometries and passages and the design of pumps that are highly efficient yet easy to maintain.

-

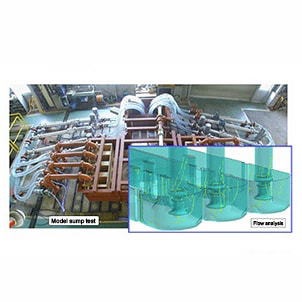

Geometry development

3D CAD modeling is used for strength evaluation and CFD analysis. The results constitute data on which to base the production of wooden patterns for casting.

-

Sump test

A model is used to search for a sump shape that generates flows without harmful vortexes.

Applicable standards

- ・ANSI/HI

- ・Turbomachinery Society of Japan (TSJ)

-

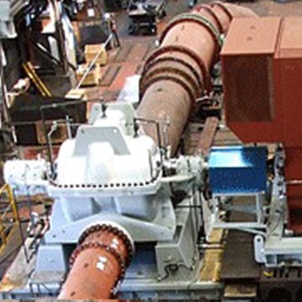

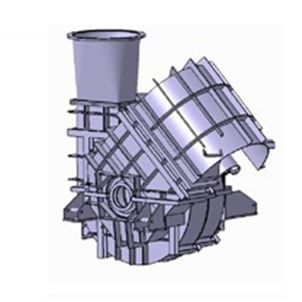

Horizontal double suction centrifugal pump

Pump performance is verified through trial runs at the factory before the pump is shipped to the customer.

-

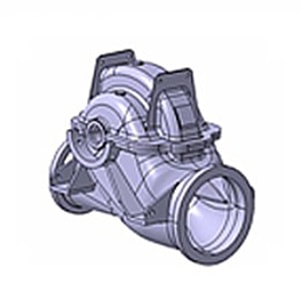

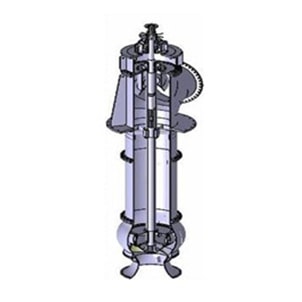

Vertical pump structural model

All vertical pump products are modeled in 3D CAD to help optimize the design.

Fan and Blower Design

DMW designs fans and blowers, which are both devices that handle gas, air, etc. According to the customer’s operating conditions and the geographical conditions of the installation location, we perform necessary analyses of CFD, strength, and other aspects, and design optimal devices that are highly efficient yet easy to maintain.

-

Geometry development

The geometry of a fan/blower is developed in 3D CAD. The produced data is used to review the geometry design, including strength analysis and interference checks with other parts, and to plan the blanking of steel plates needed for production.

-

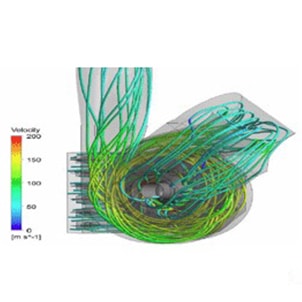

CFD analysis example

This image shows flows as strips to visualize their directions.

-

High speed standalone blower

The blower incorporates a speed increasing gear to achieve high speed rotation and smaller body size.

-

Multi-stage blower

This blower adopts a horizontally split casing for ease of maintenance. This type of blower has been installed in many oil-related companies.

Plant Design

Our plant design operations cover not only piping layout to be connected to our products but even the entire plant, including drives, valves, and control devices. Design information is shared through DMW’s networked environment to allow our teams to review it in consideration of the water hammer impact force and pressure balance, to propose optimal piping specification and layout that incorporate cutting-edge technologies, and to construct the plant as planned.

-

Design expertise

Our design engineers design specifications, layout, and controls for the device after detailed consultations with the customer.

-

Horizontal pump arrangement

The arrangement of the devices and piping is designed and proposed to be optimal for operability and maintainability.

-

Installing a vertical pump

After shipment from the factory, installation work is conducted in accordance with the execution plan.

-

Installed gas turbine

Once installation is complete, our staff will perform a test run of the device to check that it functions properly before delivery to the customer.

Electrical Design

Our electrical design team focuses on creating safe and easily operable monitoring programs, selecting suitable devices, and designing and building various electrical boards needed. After production, our devices are fully tested before shipment to verify operations under any conceivable conditions at the installation site. This enables us to deliver products that are easy to handle and satisfy customers.

-

Developing monitoring screens

Monitoring screens that suit the needs of the customer are developed according to the actual monitoring activities.

-

Central monitoring console

DMW proposes and delivers equipment designs that will make the customer’s maintenance and monitoring activities easier.

-

Photo of a switchboard

With necessary instruments optimally arranged, our electrical boards are designed and built to facilitate maintenance and monitoring activities.

-

Testing

Electrical boards are internally tested for operation under all conceivable conditions of the installation site.