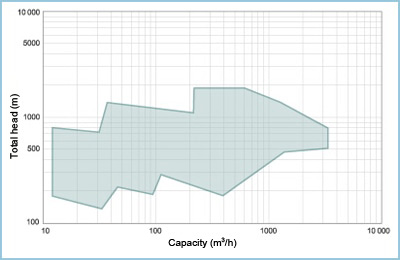

Axially Split Casing Multi-Stage Centrifugal Pump

MODEL DMF

For Oil & Gas, Petrochemical Plants, Desalination Plants, etc.

Product Outline

DMW has an established track record in delivering multi-stage pumps.

The Model DMF axially split casing multi-stage centrifugal pump is easy to maintain and provides high quality and excellent cost-effectiveness.

Major applications include crude oil transportation, boiler feed pumps, and water injection pumps.

This model fully complies with API 610-10th.

Material

| Part Name | Standard Material |

|---|---|

| Impeller | Cast steel, stainless steel, two-phase stainless steel, super two-phase stainless steel, etc. |

| Shaft | AISI 4140, stainless steel, two-phase stainless steel, super two-phase stainless steel, etc. |

| Casing | Cast steel, stainless steel, two-phase stainless steel, super two-phase stainless steel, etc. |

| Wearing ring | Stainless steel, two-phase stainless steel, super two-phase stainless steel, etc. |

Accessories

- Forced lubrication equipment

- Strainer

- Noise-proof cover

- Control panel

Delivered Projects

- Oil factory

- Type: ø250/200 axially split casing multi-stage centrifugal pump

Specification: 712 m³/h, 1,029 m, 2,650 kW

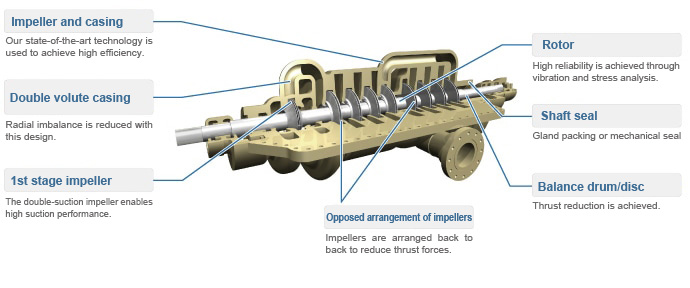

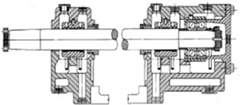

Pump Structure

Bearing Design

-

Ball bearing

The standard bearing lubrication

uses oil rings. -

Sleeve bearing + Ball bearing

This type of bearing is lubricated

by oil rings.

The bearing oil is cooled

with the shaft fan as well as

the fins mounted on the bearing housing. -

Sleeve bearing

This type of bearing is used

for heavy thrust loads.

For this combination, a forced-feed lubrication system

conforming to the API 614/610 standard is employed.