Vertical Mixed/Axial Flow Pump

MODEL VPF/VPS

For Oil & Gas, Petrochemical Plants, Power Plants, Water Supply/Drainage, Storm Water Drainage, etc.

Product Outline

DMW’s vertical mixed flow pumps, Model VPF, are used for irrigation, drainage, sewage, power plants, LNG, petrochemical plants, etc.

High reliability of the pumps is ensured through quality control as well as design verifications based on FEM/CFD analysis, model sump testing, and other methods.

Material

| Part Name | Standard Material |

|---|---|

| Impeller | Stainless steel, two-phase stainless steel, super two-phase stainless steel, etc. |

| Shaft | Stainless steel, two-phase stainless steel, super two-phase stainless steel, etc. |

| Casing | Stainless steel, cast iron, 2% nickel cast iron, Ni-Resist, two-phase stainless steel, super two-phase stainless steel, etc. |

| Wearing ring | Stainless steel, two-phase stainless steel, super two-phase stainless steel, etc. |

Accessories

- Forced lubrication equipment

- Reduction gear

- Blade angle control system

- Discharge valve

- Flexible connector

- Strainer

- Noise-proof cover

- Control panel

Delivered Projects

- Power Plant

- Type: ø3,000 double-floor type vertical adjustable-blade mixed flow pump

Specification: 91,000 m³/h, 195 kPa, 6,200 kW

- Oil factory

- Type: ø450 vertical mixed flow pump

Specification: 2,100 m³/h, 102 m, 900 kW

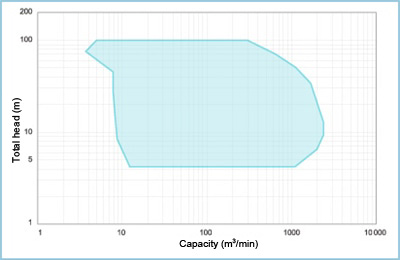

Pump Structure

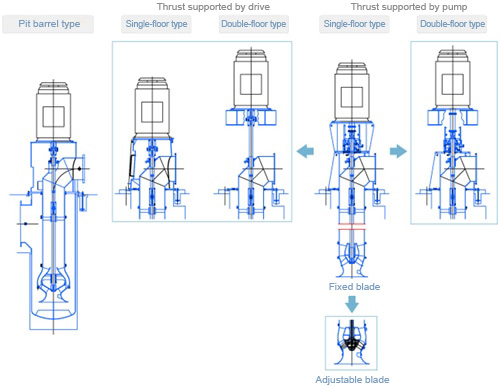

Pump Type

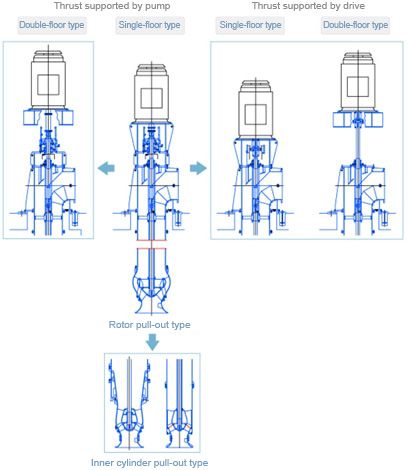

Pumps are divided into the following types.

・ Installation: Single-floor, double-floor, pit barrel

・Structure: Non-pull-out, inner cylinder pull-out, rotor pull-out

・Pump thrust: Supported by pump/by drive

・Impeller: Fixed-blade, adjustable-blade

The following aspects are considered when the actual pump type is determined.

・ Comparison of machinery costs and civil engineering costs

・Installation location and water intake level

・Maintenance and inspection

-

Non-Pull-Out Type

-

Pull-Out Type

Bearing Design

-

Thrust Bearing

The thrust bearing is installed on either the pump or drive.

For installation on the pump, the antifriction bearing or tilting pad bearing is used.

The oil-lubricated antifriction bearing is used for standard applications.

The tilting pad thrust bearing is used for high thrust applications. -

Radial Bearing

Submersible rubber bearing

Water filling is required to start operation. This type is more reliable with an established track record.Dry start bearing

There is no need to fill water to start operation. The water injection system can be omitted.

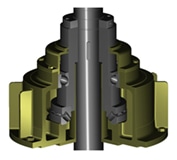

Adjustable-Blade Pump

Through stepless adjustment of the blade opening, the required capacity and total head can be achieved, allowing efficient energy use.

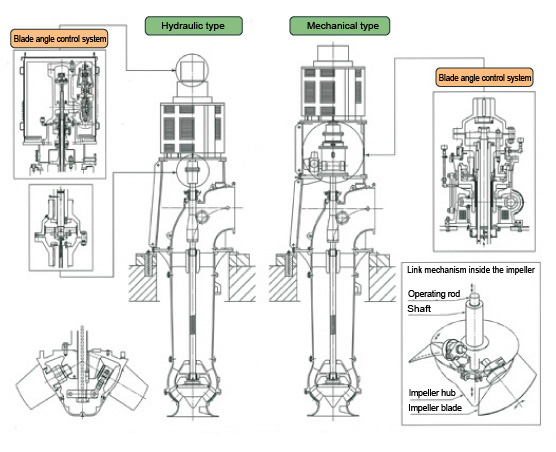

There are two types of blade angle control systems: hydraulic type and mechanical type.

The pump can be started with the impeller set at the minimum opening, and this allows starting with a small starting torque.

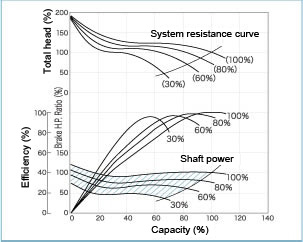

Operation near the best efficiency point can be constantly achieved.

H-Q curves, system resistance curves, and shaft power curves are shown in the chart.

The pump operating point will be the intersection of an H-Q curve and a system resistance curve.

The shaft power corresponds to the operating points on the H-Q curve.

The hatched area represents the energy to be saved.

Pump rotor

Operating characteristics of the adjustable-blade pump

Comparison of hydraulic type and mechanical type

| Hydraulic type | Mechanical type | |

|---|---|---|

| Operation power | Hydraulic pressure | Electric actuator |

| Pump size | ≥ 1,500 mm | < 2,500 mm |

| Operation mechanism | The hydraulic servo cylinder and piston are operated to move the operating rod up and down to control the blade angle. | The actuator moves the operating rod up and down through the worm gear and screw mechanism to control the blade angle. |

| Position of the blade angle control system | Above the drive unit | Between the pump and the drive unit |

| Features | ・High output. ・ Compact blade angle control system to enable lower pump height ・ Hollow drive shaft needed ・ Hydraulic unit needed |

・Suitable for medium to low output applications ・ Relatively large blade angle control system and thus greater pump height ・ No need for a hollow drive shaft ・ No need for a hydraulic unit |